WELCOME

RAM3D is the largest independent metal 3D printing service provider

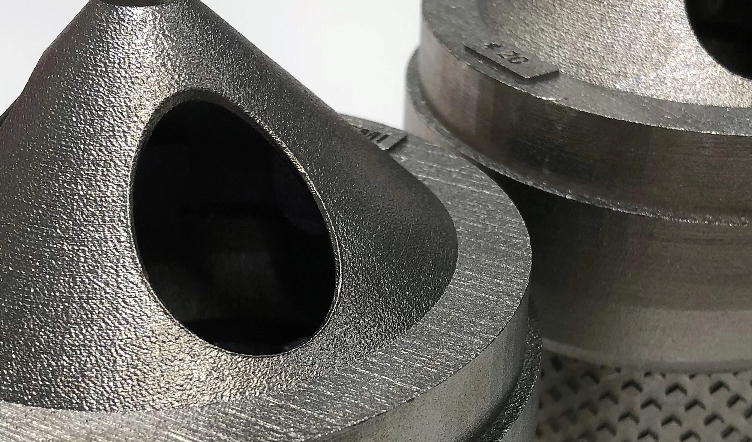

in Australasia. We are recognised leaders in Additive Manufacturing, focusing on Selective Laser Melting (SLM) in Titanium, Stainless Steel and Inconel metal alloy powders.

INDUSTRIES WE SPECIALISE IN:

THE 3D PRINTING

PROCESS

Our metal 3D printing process involves complicated and highly detailed designs to be created that wouldn’t be possible with any other technology, due to the limitations of traditional manufacturing processes. Complex design and geometry is achievable and has completely revolutionised, not only how we work, but what we can create.